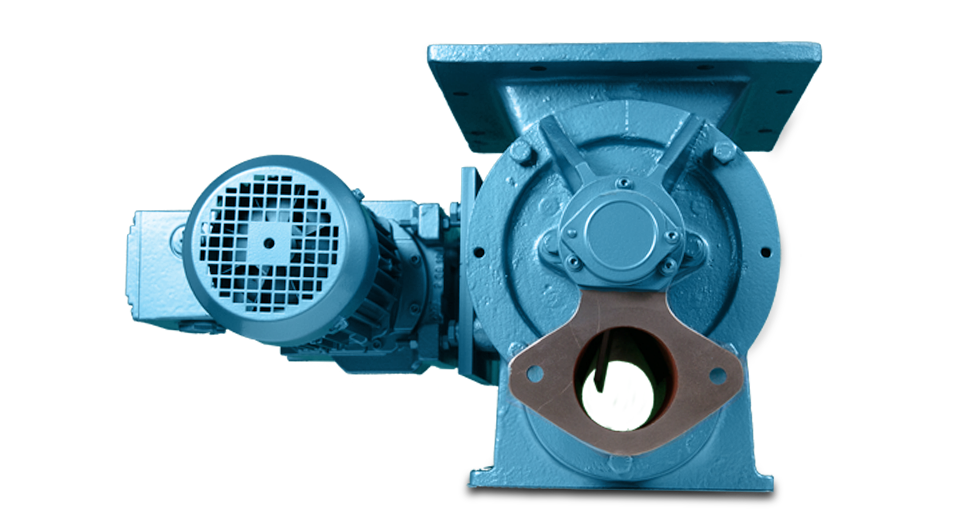

Basic in many sectors, dust collection systems help to maintain clean air, reduce health hazards, and advance generally by and large work environment security. Of the most important components in these systems is most likely the rotary valves, a device essential for the efficient evacuation of dust and various particulates.

- Accurate Material Movement

Rotary valves are meant to provide exact command over the dust and particle matter flow. They ensure that the collection framework releases dust at a consistent rate, which is absolutely essential for maintaining appropriate wind stream and framework efficiency. Without a rotary valve, dust could either be delivered intermittently, therefore affecting generally speaking performance, or gather in the framework and cause obstructions.

- Pressure Maintenance’s Airlock Function

The rotary valve’s ability to run almost as an airlock and maintain the pressure balance within the dust collection system is crucial. In systems where gaseous tension is a key variable—such as those comprising pneumatic conveying or vacuum applications—the rotary valve guarantees smooth activity by keeping air from moving away or entering. This airlock spotlight reduces energy misfortune, so supporting the dust collection system in maintaining its effectiveness. Dust collecting systems may experience air leaks without this component, which would reduce performance and increase functional costs.

- Versatility and Durability

Working under extreme industrial conditions—including openness to grating materials, high temperatures, and continuous activity—rotary valves are built to resist. For dust collecting systems in sectors such as concrete, food handling, mining, and carpentry, where dust collecting is a regular and demanding activity, this longevity makes them a great choice. Moreover, rotary valves are flexible for different uses since they can handle several materials, from fine dust particles to larger flotsam and jetsam.

- Control of Blockages and Dust Build-Up

The possibility of dust buildup in dust collecting systems is one of the main concerns since it can lead to bottlenecks and reduce the framework production. Rotary valves ensure a controlled and uninterrupted release of dust from the framework, helping to reduce this gamble. Rotary valves help to maintain the framework moving as intended by preventing dust collection and hence saving maintenance margin time.

Essential components in dust collection systems, rotary valves provide exact material management, maintain pressure balance, and prevent dust buildup by themselves. Their ability to operate as airlocks and handle various materials makes them essential in ensuring the seamless and effective operation of dust collection systems over many sectors.